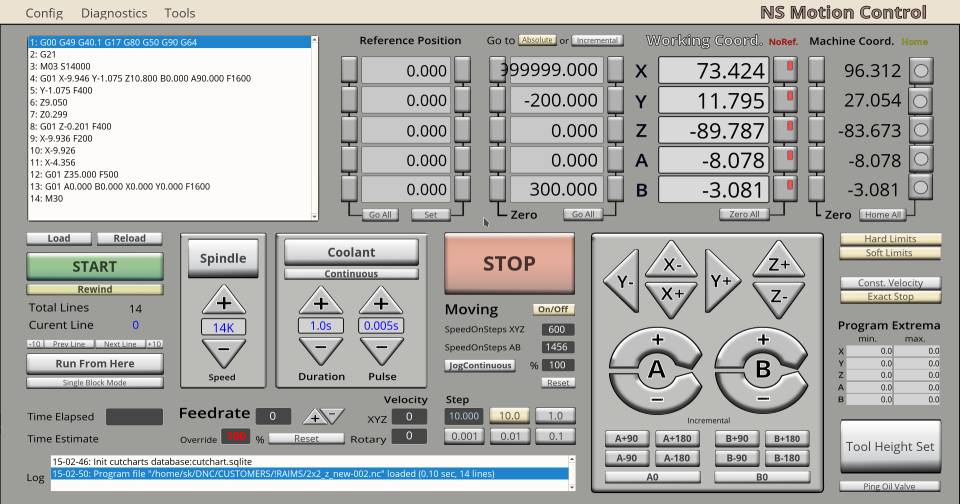

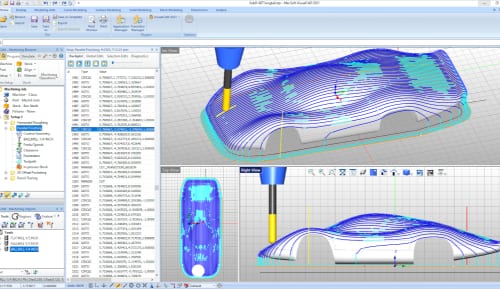

Holding tag parameters are defined in the Edit → Preferences → Path → Dressups tab.Colors are defined in the Edit → Preferences → Path → Path colors tab.The Macro file path, and Geometric tolerances, are defined in the Edit → Preferences → Path → Job Preferences tab.The Postprocessor configuration defines the final G-code units. The FreeCAD 3D model units are defined in the Edit → Preference → General → Units tab's Units settings.The Path Workbench has external dependencies including: It links the Postprocessor, and allows importing and exporting Job Templates. The Path Workbench provides a Tool Manager (Library, Tool-Table), and G-code Inspection, and Simulation tools. The list is populated by adding Path Operations, Path Dressups, Path Supplemental Commands, and Path Modifications from the Path Menu, or GUI buttons. The Job Workflow lists these in the order they will be executed. The G-code is generated from directives and Operations contained in a Path Job. The Path Workbench generates G-code defining the paths required to mill the Project represented by the 3D model on the target mill in the Path Job Operations FreeCAD G-code dialect, which is later translated to the appropriate dialect for the target CNC controller by selecting the appropriate postprocessor. This step is called post processing there are different post processors available. Export the job with a G-code, matching to your machine.These Path objects use internal FreeCAD G-code dialect, independent of the CNC machine.

These produce real-world 3D objects on CNC machines such as mills, lathes, lasercutters, or similar. The Path Workbench is used to produce machine instructions for CNC machines from a FreeCAD 3D model.

0 kommentar(er)

0 kommentar(er)